MAGNABEND HAGAHA toogashada dhibka

Tilmaamaha Toogashada Dhibaatada

Kuwa soo socdaa waxay khuseeyaan mashiinada Magnabend ee ay samaysay Magnetic Engineering Pty Ltd ilaa sanadka 2004.

Tan iyo markii uu dhacay shatiyada (ay leedahay Magnetic Engineering) warshado kale ayaa hadda sameynaya mashiinada Magnabend kuwaas oo laga yaabo inaysan isku mid ahayn.Sidaa darteed xogta hoose lagama yaabo inay khusayso mashiinkaaga ama waxay u baahan kartaa in la waafajiyo.

Sida ugu fudud ee lagu xallin karo mashaakilaadka korantada waa in laga dalbado soo saaraha beddelka moduleka korantada.Tan waxaa lagu bixiyaa sarif, sidaas darteedna waa mid si macquul ah loo qiimeeyay.

Kahor intaadan dirin moduleka beddelka waxaad jeclaan kartaa inaad hubiso kuwan soo socda:

Haddii mishiinku gabi ahaanba shaqayn waayo:

a) Hubi in korantadu ay ka heli karto mishiinka adiga oo eegaya nalka duuliyaha ee shid/damisan.

b) Haddii korontadu ay jirto balse mishiinku weli dhintay balse uu dareemayo kuleyl aad u kulul markaas waxaa dhici karta in kulaylku gooyay.Xaaladdan oo kale sug ilaa mishiinku qaboojiyo (qiyaastii ½ saac) ka dibna mar kale isku day.

c) Labada gacmood ee bilawga ah waxay u baahan yihiin in badhanka START la riixo ka hor inta aan gacanta la jiidin.Haddii gacanta marka hore la jiido markaa mashiinku ma shaqayn doono.Sidoo kale waxa dhici karta in laydhka foorarsiga ahi dhaqaaqo (ama uu ku dhaco) si ku filan si uu ugu shaqeeyo "angle microswitch" ka hor inta aan la riixin badhanka START.Haddii ay tani dhacdo iska hubi in gacanta si buuxda dib loogu riixay marka hore.Haddii tani ay tahay dhibaato joogto ah markaas waxay muujinaysaa in mishiinka mikroswitch u baahan yahay hagaajin (hoos eeg).

d) Suurtagalnimada kale ayaa ah in badhanka START uu khalad yahay.Haddii aad haysato Model 1250E ama ka weyn markaa eeg haddii mishiinka lagu bilaabi karo mid ka mid ah badhamada START ee kale ama footswitch.

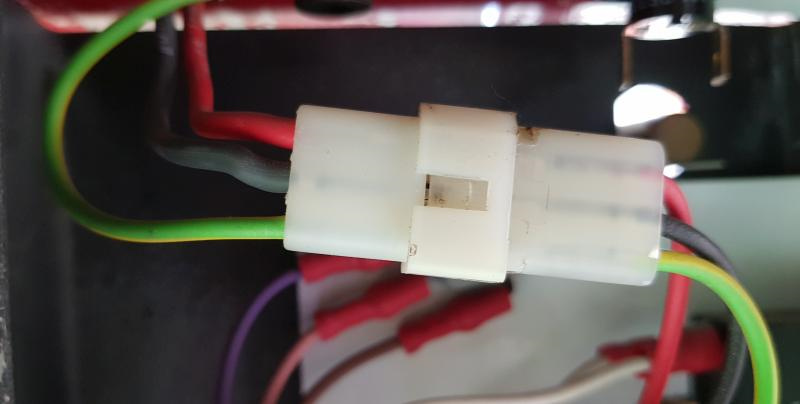

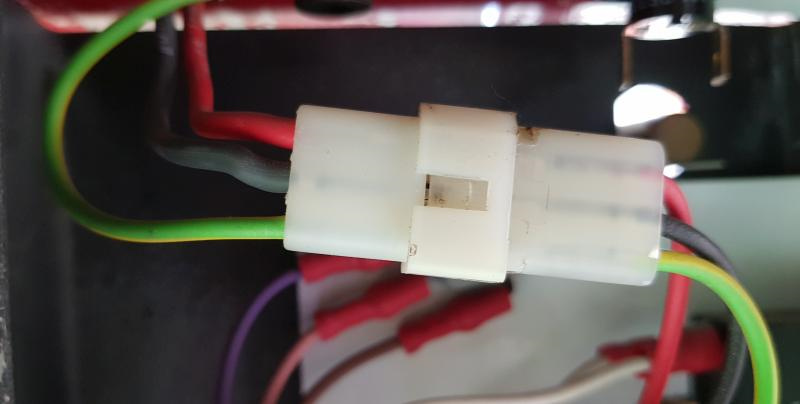

e) Sidoo kale hubi isku xirka naylon ee ku xiraya moduleka korantada iyo gariiradda magnetka.

f) Hadii xajintu shaqayn waydo balse xajintu hoos u dhacdo marka la sii daayo badhanka START markaas tani waxay tusinaysaa in 15 microfarad (10 µF on 650E) capacitor uu cilad leeyahay oo u baahan doona in la bedelo.

Haddii mashiinku uu afuufo fiyuusyada dibadda ama uu safro jebiyayaasha wareegga:

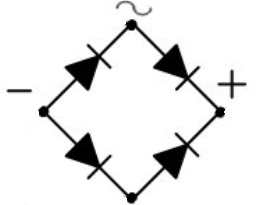

Sababta ugu badan ee hab-dhaqankan ayaa ah buundada-hagaajinta oo la afuufay.Rectifier-ga la afuufay ayaa sida caadiga ah yeelan doona ugu yaraan mid ka mid ah 4-ta diode ee gudaha ah oo gaaban.

Tan waxaa lagu hubin karaa multimeter.Iyada oo mitirku uu saaran yahay cabbirkiisa iska caabbinta ugu hooseeya hubi inta u dhaxaysa lamaane kasta.Mid ka mid ah polarity ee hogaaminta tijaabinta multimeterka waa in ay muujisaa infinity ohms iyo polarity-ga rogan waa in uu muujiyaa akhris hoose, laakiin ma aha eber.Haddii wax akhrinta iska caabintu eber tahay markaas toosiyaha waa la afuufi waana in la beddelaa.

Hubi in mishiinku ka go'an yahay meesha korontada laga saaro ka hor inta aanad isku dayin dayactir gudaha ah.

hagaajin ku habboon beddelka:

Qaybaha RS nambarka qaybta: 227-8794

Ugu badnaan hadda: 35 amps joogto ah,

koronto-celinta ugu badan: 1000 Volts,

Terminalka: 1/4" degdeg ah ama 'Faston'

Qiimaha qiyaastii: $12.00

Sababta kale ee suurtogalka ah ee jabka ayaa ah in gariiradda magnetka laga yaabo in lagu soo gaabiyo jirka magnetka.

Si aad taas u hubiso ka fur xidhiidhiyaha gariiradda birlabeedka oo cabbir iska caabbinta, laga bilaabo rasaasta cas ama sunta madow, ilaa jidhka magnetka.U deji multimitirka ilaa xadka u sarreeya ee iska caabbinta.Tani waa inay muujisaa infinity ohms.

Sida habboon cabbirkan waa in lagu sameeyaa "Megger meter".Mitirka noocaan ah wuxuu ku eegayaa iska caabbinta iyadoo la adeegsanayo danab sare (sida caadiga ah 1,000 volts).Tani waxay heli doontaa dhibaatooyin badan oo dahaarka ah oo ka sii dahsoon marka loo eego kuwa lagu heli karo multimeterka caadiga ah.

Burburka dahaarka u dhexeeya gariiradda iyo jidhka magnetka waa dhibaato halis ah oo caadiyan waxay u baahan tahay in gariiradda laga soo saaro jidhka magnetka si loo dayactiro ama loogu beddelo gariirad cusub.

Haddii isku xidhka nalka uu shaqeeyo laakiin isku xidhka buuxa aanu shaqayn:

Hubi in "Angle Microswitch" si sax ah loo dhaqaajiyay.

[Dawiishkan waxa ku shaqeeya naxaas afar gees ah (ama wareeg ah) kaas oo ku dheggan habka tilmaamaya xagasha.Marka gacanta la jiido laydhka foorarsigu wuu rogrogaa kaas oo siinaya wareegtada mishiinka naxaasta ah.Dhaqdhaqaaquhu isna wuxuu ku shaqeeyaa microswitch gudaha golaha korantada.]

Dhaqdhaqaaqa Microswitch ee Model 1000E

(Habab kale ayaa isticmaala mabda'a la mid ah)

Dhaqdhaqaaqa sida lagu arkay gudaha korantada

shirka.

Ka soo saar gacanta oo gudaha soo geli

Haddii daaruhu uusan taxin ON iyo OFF ka dibna u lul laydhka foorarsiga midigta sare si qalabka naxaasta loo arko.U rog rog rogmada kor iyo hoos.Wax-qabadku waa inuu u rogmadaa si uu uga jawaabo laydhka foorarsan (ilaa uu ku qabsado joogsigiisa).Haddii aysan taasi dhicin markaas waxay u baahan kartaa xoog xajin:

- 650E iyo 1000E xoogga xajintu waa la kordhin karaa iyadoo la saarayo qalabka naxaasta ah oo la tuujiyo daloolka xiran (tusaale ku xigeenka) ka hor inta aan dib loo rakibin.

- Marka la eego 1250E la'aanta xoogga xajintu waxay inta badan la xiriirtaa labada boolal ee koofiyadda M8 ee labada gees ee shafka wax-qabadka oo aan adkeyn.

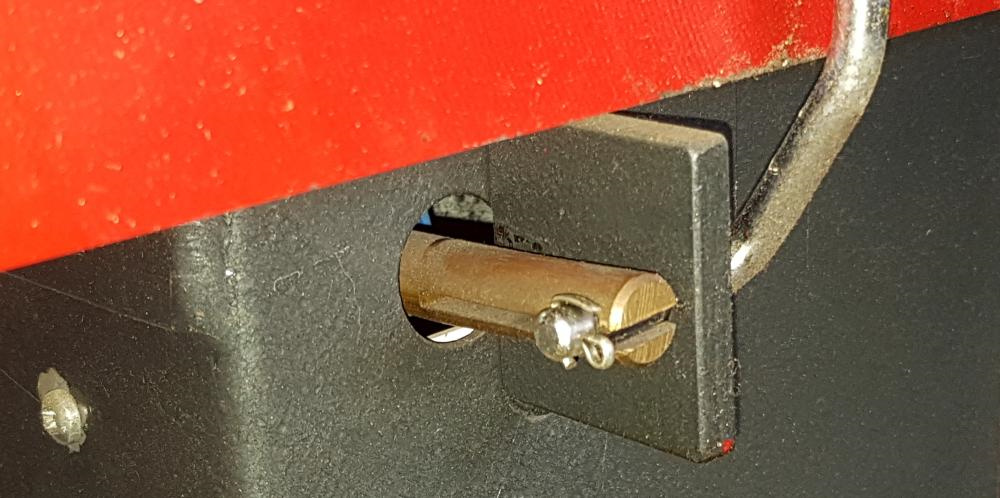

Haddi hawlgeliyaha uu wareego oo uu xajiyo OK balse aanu wali gujin microswitch markaas waxa laga yaabaa inay u baahato hagaajin.Si tan loo sameeyo marka hore mishiinka ka saar meesha korontada ka dibna ka saar guddiga gelitaanka korantada.

a) Model-ka 1250E barta shidku waxa lagu hagaajin karaa iyada oo la rogayo furaha dhex mara mishiinka.furka waa in la hagaajiyo si uu dareemahu riixo marka cidhifka hoose ee laydhka foorarsiga uu dhaqaaqo ilaa 4 mm.(Marka la eego 650E iyo 1000E isla hagaajinta ayaa lagu gaaraa iyada oo la foorarsado cududda microswitch.)

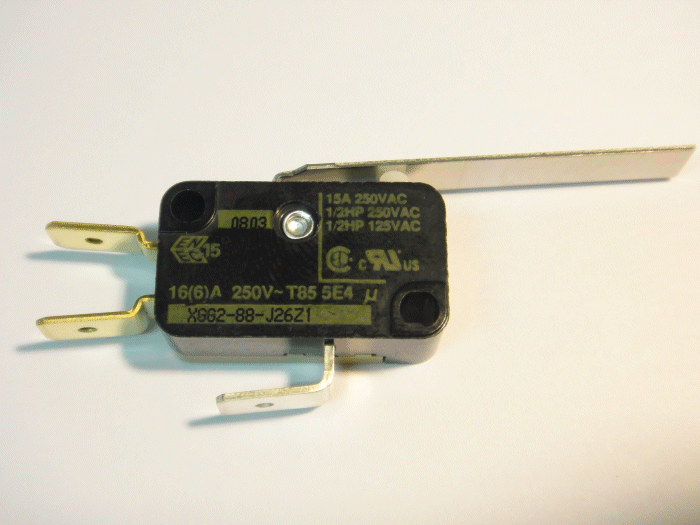

b) Haddii microswitch-ku aanu taxin ON iyo OFF inkasta oo hawl-galiyuhu si fiican u shaqaynayo markaa furaha laftiisa ayaa laga yaabaa inuu ku dhex milmo oo wuxuu u baahan doonaa in la beddelo.

Hubi in mishiinku ka go'an yahay meesha korontada laga saaro ka hor inta aanad isku dayin dayactir gudaha ah.

Beddel ku habboon V3:

Qaybta RS lambarka: 472-8235

Qiimaynta hadda: 16 amps

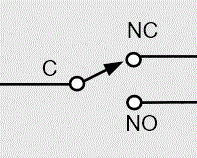

V3 Wareegga

C = 'caado'

NC= 'si caadi ah u xidhan'

MAYA= 'si caadi ah u furan'

c) Haddii mashiinkaagu uu ku rakiban yahay furaha caawinta markaa hubi in loo beddelay booska "caadiga ah".(Kaliya isku xidhka nalka ayaa la heli karaa haddii dabeedku ku jiro booska "AUX CLMP".)

Haddii isku dhejinta ay fiican tahay laakiin Clampbars ma sii daayaan marka mishiinku damiyo:

Tani waxay tusinaysaa guuldarada ku timaadda wareegga dib-u-dejinta garaaca wadnaha.Sababta ugu macquulsan waa iska caabin koronto oo ah 6.8 ohm.Sidoo kale hubi dhammaan diodes-yada iyo sidoo kale suurtogalnimada in ay ku dhegganaadaan xiriirada gudbinta.

Iska caabin ku habboon beddelka:

Cunsurka14 qaybta No. 145 7941

6.8 ohm, 10 watt qiimaynta korantada.

Qiimaha caadiga ah $1.00

Haddi mashiinku laabmi waayo xaashida cabbirka culus:

a) Hubi in shaqadu ku dhex jirto qeexida mishiinka.Si gaar ah u ogow in 1.6 mm (cabir 16) qaloocinta bararka kordhinta waa in lagu rakibaa laydhka foorarsiga iyo in ballaca dibnaha ugu yar yahay 30 mm.Tani waxay ka dhigan tahay in ugu yaraan 30 mm walax ay tahay inay ka soo baxaan cidhifka foorarsiga ee xajinta.(Tani waxay khusaysaa aluminium iyo birta labadaba.)

Bushimaha cidhiidhiga ah waa suurtogal haddii laabladu aanay ahayn dhererka buuxa ee mishiinka.

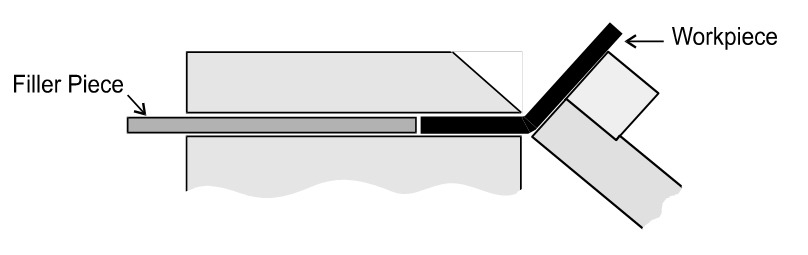

b) Sidoo kale haddi shaqadu ay buuxin waydo booska ka hooseeya clampbar markaas wax qabadku wuu saamayn karaa.Natiijooyinka ugu wanaagsan had iyo jeer ku buuxi booska ka hooseeya clampbar bir qashinka ah oo dhumucdiisuna tahay tan shaqada.(Xajinta magnetka ugu fiican qaybta buuxintu waa inay noqotaa bir xitaa haddii shaqadu aanay ahayn bir.)

Tani sidoo kale waa habka ugu wanaagsan ee loo isticmaalo haddii loo baahan yahay in laga sameeyo bushimo aad u cidhiidhi ah oo ku saabsan shaqada.