KALAMPBAR-KA QARXOON

Magnabend Slotted Clampbar

Xakamaynta xadhkaha goosatay waa mid ka mid ah dhowr waxyaalood oo cusub oo loo sameeyay mishiinka laalaabida xaashida ee Magnabend.

Waxay bixisaa foorarsiga sanduuqyada gacmeedka iyo saxarada iyada oo aan loo baahnayn "faraha" la hagaajin karo.

Qaybaha u dhexeeya boosaska xajintan waxay u dhigantaa faraha la hagaajin karo ee mishiinka bireega caadiga ah, laakiin leh clampbar-ka Magnabend weligood uma baahna in la hagaajiyo sababtoo ah naqshadeynta ayaa bixisa dhammaan cabbirrada!

Hal-abuurkani waxa uu ka dhashay indho-indhaynta soo socota:-

Marka hore waxaa la ogaaday in aysan muhiim ahayn in la helo gees foorarsi joogto ah sababtoo ah qalloocintu waxay ka gudbi doontaa faraqyo macquul ah oo ka tagay faraha dhexdooda iyada oo aan wax saameyn ah oo muuqda ku yeelan laabashada waa haddii ay farahu si fiican u siman yihiin, mar walbana waxay si fiican u siman yihiin meelaha la jeexjeexay. clampbar sababtoo ah waxay leedahay "faro go'an".

Marka labaad waxaa la ogaaday in iyadoo si taxadar leh loo habeeyey boosaska ay suurtogal tahay in la bixiyo tiro aan la qiyaasi karin oo cabbirro ah ilaa ku dhawaad dhererka buuxa ee clampbar.

Marka saddexaad waxaa la ogaaday in helista boosaska ugu wanaagsan boosaska aysan ahayn dhibaato fudud.

Inkasta oo ay yar tahay haddii tiro badan oo boosas ah la bixiyo.

Laakiin dhibaatada xiisaha leh ayaa ah in la helo tirada ugu yar ee boosaska kuwaas oo bixin doona dhammaan cabbirrada.

Waxa ay u muuqatay in aanay jirin xal lafo-gur ah oo lagu xallinayo dhibaatadan.Xaqiiqdaasi waxay u noqotay qaar xiiseeya xisaabyahannada Jaamacadda Tasmania.

Si kastaba ha ahaatee dhibaatada waxaa xaliyay injineerada Magnetic Engineering (badanaa Mr Geoff Fenton) kuwaas oo la yimid barnaamij kombuyuutar ah oo isticmaalay "Monte Carlo Method" si loo helo booska ugu fiican ee boosaska.Barnaamijkani waxa uu isticmaalay koronto-dhaliye nambarka random-ka si uu u bixiyo qiyaas boosas kuwaaso markaas lagu tijaabin doono male hore oo ugu fiicnaa ee boosas.Markaa malaayiin suurtagal ah ayaa la tijaabin karaa.

Boosaska Afyare ee La Habeeyay ee 4 Qaababka Magnabend:

Jagooyinka lagu muujiyey shaxda hoose waxa laga cabbiraa dhinaca bidix ee xajinaha oo waa badhtamaha boosaska.

Balac kastaa waa 8mm ballac.

Tilmaamaha moodeelku waxay muujinayaan dhererka foorarsiga magaca ee moodeelka.Dhererka dhabta ah ee nooc kasta waa sida soo socota:

Qaabka 650E: 670mm, MUUQAALKA 1000E: 1050mm, MUUQAALKA 1250E: 1300mm, MUUQAALKA 2000E: 2090mm.

Dhererka guud ee xajmiyada xajinta oo ay ku jiraan qabsashada faraha ee cidhif kasta: ku dar 20mm dhererka sare.

Cabbirka qoto dheer ee boosaska laguma muujin sawirka kore.Tani waa xoogaa ikhtiyaari ah laakiin qoto dheer 40 ilaa 50 mm ayaa la soo jeediyay.

| Afyare No. | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 21 | 22 | 23 | 24 | 25 | 26 | 27 | 28 | 29 | 30 | 31 |

| Qaabka 650E | 65 | 85 | 105 | 125 | 155 | 175 | 195 | 265 | 345 | 475 | 535 | 555 | 575 | 595 | 615 | ||||||||||||||||

| Qaabka 1000E | 65 | 85 | 105 | 125 | 155 | 175 | 195 | 215 | 385 | 445 | 525 | 695 | 755 | 835 | 915 | 935 | 955 | 975 | 995 | ||||||||||||

| Qaabka 1250E | 65 | 85 | 105 | 125 | 155 | 175 | 195 | 215 | 345 | 465 | 505 | 675 | 755 | 905 | 985 | 1065 | 1125 | 1165 | 1185 | 1205 | 1225 | 1245 | |||||||||

| Qaabka 2000E | 55 | 75 | 95 | 115 | 135 | 155 | 175 | 265 | 435 | 455 | 555 | 625 | 705 | 795 | 945 | 1035 | 1195 | 1225 | 1245 | 1295 | 1445 | 1535 | 1665 | 1695 | 1765kii | 1795kii | 1845kii | 1955kii | 1985kii | 2005 | 2025 |

SAMEYNTA TARIINADA ADIGA OO LA ISTICMAALO XILDHIBAAN

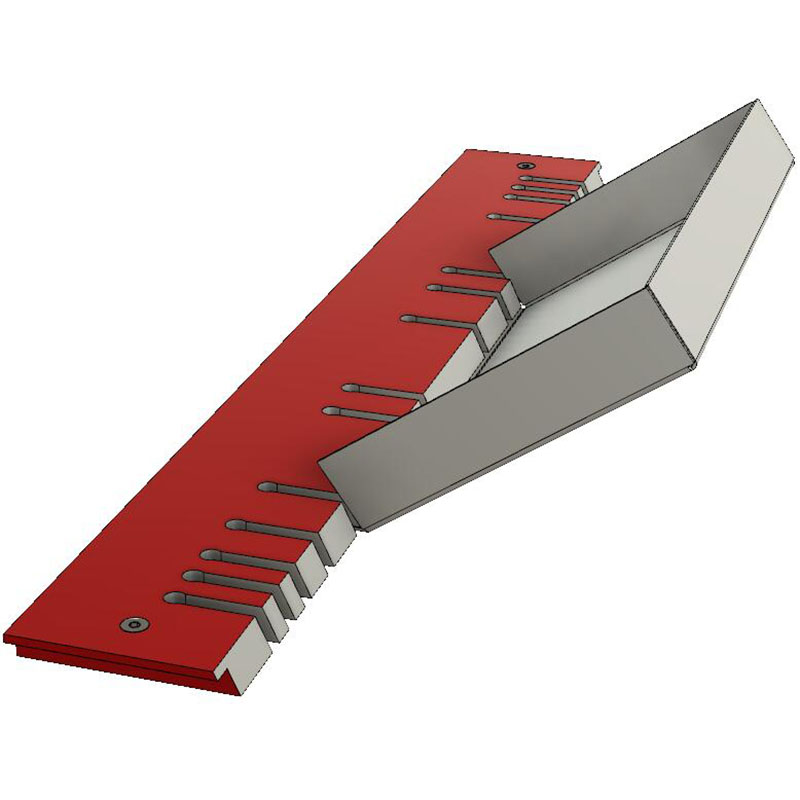

Clampbar-ka Slotted, marka la keeno, wuxuu ku habboon yahay samaynta saxaarad-gacmeedka iyo digsiyada si degdeg ah oo sax ah.

Faa'iidooyinka clampbar-ka-xiran ee ka sarreeya xirmooyinka gaagaaban ee xajinta ee samaynta saxarada ayaa ah in cidhifka foorarsiga uu si toos ah ula jaanqaado mishiinka intiisa kale, iyo clampbar-ku si toos ah ayuu kor ugu qaadayaa si uu u fududeeyo gelinta ama ka saarista qalabka shaqada.Marnaba-wax-yar, xargaha gaaban ayaa loo isticmaali karaa in lagu sameeyo saxaarad qoto dheer oo aan xadidnayn, dabcan, way ku fiican yihiin samaynta qaabab adag.

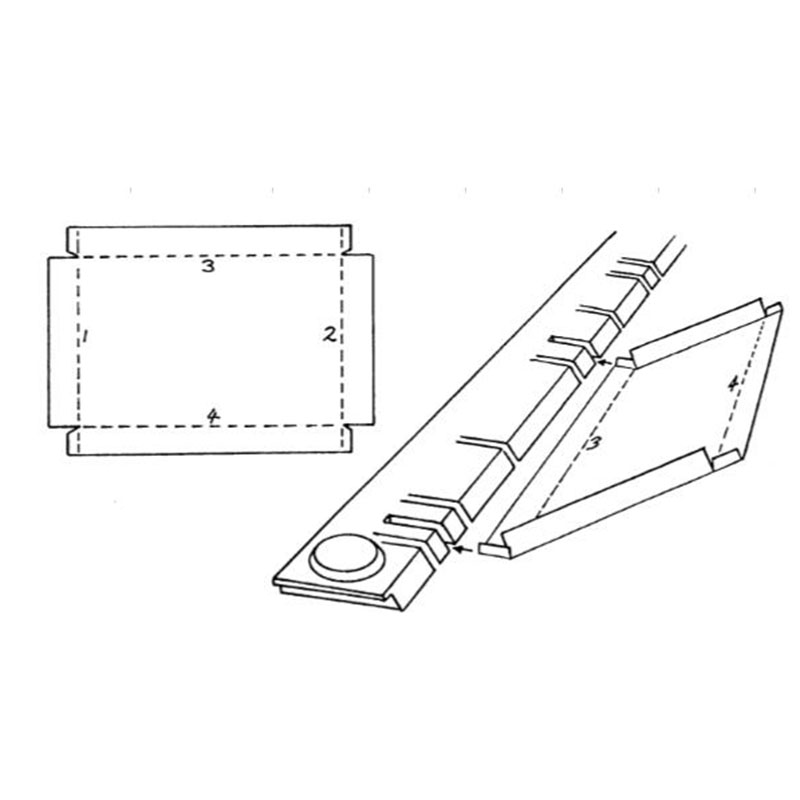

Isticmaalka, boosasku waxay u dhigmaan faraqa u dhexeeya faraha sanduuqa caadiga ah & mashiinka laalaabida digsiga.Balaadhka boosasku waa sida in laba boos oo kasta ay ku dhejiyaan saxaarad ka badan 10 mm, tirada iyo meelaha boosaska ay ka kooban yihiinna waa sida in dhammaan cabbirrada saxaaraduhu, mar walba la heli karo laba boos oo ku habboon. .

Si aad u laabiso saxaarad-gacmeed:

Isku laab labada dhinac ee hore ee iska soo horjeeda iyo tabaha geesaha adiga oo isticmaalaya xajinta xajinta laakiin iska indha tiraya joogitaanka boosaska.Boodhadhkani wax saamayn ah oo la arki karo kuma yeelan doonaan laalaabka la dhammeeyey.

Hadda dooro laba boos oo u dhexeeya kuwaas oo la iskulaabi karo labada dhinac ee soo hadhay.Tani dhab ahaantii waa mid aad u fudud oo degdeg ah.Kaliya saf dhinaca bidix ee saxaaradda qayb laga sameeyay oo leh booska bidix oo arag haddii uu jiro boos dhinaca midig ah oo lagu riixayo;Haddaysan ahayn, ku sidi saxanka ilaa dhinaca bidix ka yahay booska xiga oo isku day mar kale.Caadi ahaan, waxay qaadataa ilaa 4 isku day oo noocaas ah si loo helo laba boos oo ku habboon.

Ugu dambeyntii, cidhifka saxaarada oo ka hooseeya xajinta iyo inta u dhaxaysa labada boos ee la doortay, laabi dhinacyada hadhay.Dhinacyadii hore loo sameeyay waxay galayaan boosaska la doortay marka laalaabyada ugu dambeeya la dhammeeyo.

Dhererka saxaaradda oo ku dhow ilaa iyo inta uu le'eg yahay xajinta waxa laga yaabaa inay lagama maarmaan noqoto in la isticmaalo hal daraf oo xajinta meel bannaan oo bannaan ah.

Sanduuqyada-Slotted Clampbar Isticmaalka Clampbar Slotted

Waqtiga boostada: Jun-03-2023