ELECTROMAGNETIC XAASHIDA faylalka

| JDCBEND - USER BUUGGA for MUUQAALADA 2000E, 2500E & 3200E |

Nuxurka

HORDHAC3

GOLAHA4

QAABKA6

XAASHIDA KORMEERKA10

ADEEGSIGA JDCBEND:

HAWLGALKA12

ISTICMAALKA DHAQANKA DHAQANKA13

FARUUR LA LABAY14

GELIN GELIN15

SAMEYNTA QAYB IMTIXAANKA16

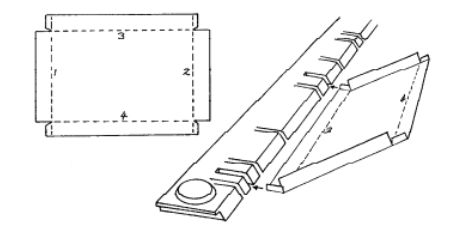

SANDUUQYADA (XILDHIBAANADA GAABAN) 18

XAALADAHA (QALABKA QARXOON) 21

ACCESSORY AWOODDA SHEAR 22

XAQA 23

Dayactirka 24

toogashada dhibka 25

GUDOONKA 28

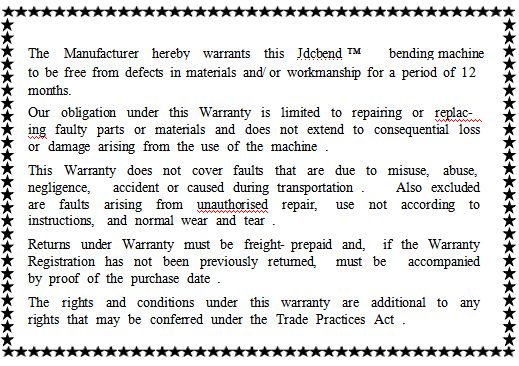

DAMMAANKA 30

DIIWAAN GELIN 31

Ganacsade's Magaca & Cinwaanka:

________________________________________________

________________________________________________

________________________________________________

Macmiil's Magaca & Cinwaanka:

________________________________________________

________________________________________________

________________________________________________

________________________________________________

Jawaabahaaga su'aalaha soo socda waa la mahadin doonaa:

(Fadlanhoosta ka xariiqkelmadda ama ereyada ku habboon)

Sidee sameeyey adiga baro of ah Jdcbend ?

Bandhigga Ganacsiga, Xayeysiiska, Iskuulka ama Kulliyada, Wax kale _____________

Waa kuwee is kaaga qaybta of isticmaal?

Dugsiga, Kulliyadda Farsamada, Jaamacadda, Tubiyaasha, Aqoon-is-weydaarsiga Dayactirka, Dayactirka Baabuurta, Aqoon-is-weydaarsiga Elektrooniga, Aqoon-is-weydaarsiga taageerada cilmi-baarista,

Aqoon-is-weydaarsiga wax-soo-saarka, dukaanka xaashida, aqoon-is-weydaarsiga shaqada,

Wax kale ______________________________________

Waa maxay nooca of biraha doono adiga sida caadiga ah foorarsi?

Bir khafiif ah, aluminium, bir aan daahin, Copper, Zinc, naxaas

Mid kale _________________________________

Waa maxay dhumucdiisuna'?

0.6 mm ama ka yar, 0.8 mm.1.0 mm, 1.2 mm, 1.6 mm

Faallo:

(Tusaale: Mashiinku ma sameeyaa waxaad filaysay?)

Kadib markaad buuxiso, fadlan foomkan ku dheji ciwaanka bogga 1.

Fadlan buuxi tixraacaaga:

Qaabka _____ Taxane No.__________ Taariikhda la iibsaday __________

Magaca iyo Ciwaanka iibiyaha: ________________________________

________________________________

________________________________

________________________________

Kahor intaadan u soo celin mashiinkaaga dayactirka dammaanadda, fadlan la xiriir

Soo saaraha si uu ugala hadlo habka ugu waxtarka badan ee gaadiidka iyo baakadaha

iyo in dhammaan ama qayb ka mid ah mishiinka loo baahan yahay in lagu celiyo

warshada .

Si loo caddeeyo taariikhda iibka, fadlan soo celi Diiwaangelinta damaanada

bogga soo socda.

Waxaa lagugula talinayaa inaad la xiriirto soo saaraha ka hor inta aan dayactirku hoos loo dhigin.

gaar ahaan marka la isticmaalayo qandaraaslayaasha dibadda .Damaanad qaadku ma sameeyo

daboosho kharashaadka qandaraaslayaashan haddii aan la qabanqaabin hore loo samayn

sameeyey .

The JdcbendMashiinka foorarsiga xaashida waa mid aad u wanagsan oo sahlan in loo isticmaalo mishiinka foorarsiga dhammaan noocyada xaashida birta sida aluminium, cop-per, birta, iyo birta.

The elektromagnetic xajin nidaamkawaxay siisaa xoriyad dheeraad ah si ay u samayso qaybta shaqada ee qaabab adag .Way fududahay in la sameeyo kanaalo cidhiidhi ah oo qoto dheer, qaybo xidhan, iyo sanduuqyo qoto dheer oo adag ama aan macquul ahayn mashiinka caadiga ah.

The gaar ah ku dheggan nidaamkaloo isticmaalo laydhka foorarsigu wuxuu bixiyaa mishiin dhamaystiran oo furfuran sidaas awgeed waxay si weyn u kordhinaysaa wax-qabadkeeda.Naqshadeynta istaagu waxay sidoo kale gacan ka geysataa isku-bedelka mashiinka iyadoo la siinayo saameyn "cudud-free" ah cidhifyada mishiinka.

Fudud of isticmaalWaxay ka timaaddaa xakamaynta caarada faraha ee isku-qabsiga iyo is-qabsiga, fudaydka iyo saxnaanta laab-laabashada, iyo hagaajinta tooska ah ee dhumucda xaashida.

Asal ahaanIsticmaalka xajinta birlabeedka macneheedu waxa weeye in culayska foorarsiga si sax ah loo qaado meesha ay ka soo baxaan;ciidamada ma aha in lagu wareejiyo dhismooyinka taageerada ee cidhifyada mishiinka .Tani waxay la macno tahay in xubinta isku dhejinta aysan u baahnayn wax badan oo dhismo ah oo markaa laga dhigi karo mid aad u cufan oo yar oo caqabad ah .(Dhumucda clampbarka waxaa lagu go'aamiyaa kaliya shuruudaheeda si loo qaado qulqulka birlabeedka ee ku filan oo aan la eegayn tixgalinta qaabdhismeedka gabi ahaanba).

Gaar ah xuddun la'aan xarun hindhisyadawaxaa loo sameeyay Jdcbend waxaana lagu qaybiyaa dhererka laydhka foorarsiga oo sidaas darteed, sida clampbar-ka, qaado culeyska foorarsiga meel u dhow halka laga soo saaray.

Saamaynta isku dhafan eebirlab xajinleh kuwa gaarka ahxuddun la'aan hindhisyadamacneheedu waxa weeye in Jdcbend uu yahay mid aad isku xidhan, meel badbaadinaya, mishiin leh miisaan aad u sarreeya oo xoog iyo miisaan leh.

To heli ah inta badan baxay of kaaga mashiinkaIsticmaalayaasha waxaa lagu booriyay inay akhriyaan buug-gacmeedkan, gaar ahaan qaybta cinwaankeedu yahay ISTICMAALKA JDCBEND.Fadlan sidoo kale soo celi DIIWAANGELINTA DAMMAANKA sababtoo ah tani waxay fududaynaysaa wixii sheegasho ah ee dammaanadda iyo sidoo kale waxay siinaysaa soo-saaraha diiwaanka ciwaankaaga kaas oo fududaynaya in macaamiisha lala socodsiiyo wixii horumar ah ee iyaga ka faa'iideysan kara.

GOLAHA ...

GOLAHA TILMAAMAHA

1. Ka soo saar dhammaan alaabta sanduuqamarka laga reeboJDCBEND ugu weyn™mashiinka.Soo hel baakadda xirmooyinka iyo furaha Allen 6mm.

2. Isticmaalka dharbaaxayaasha la siiyay, kor u qaad cidhif kasta oo ka mid ahmashiinkaoo ku dul dhig alwaaxyo simbiriirixan oo sanduuqa dushiisa furan.(Laba xabo oo alwaax ah ayaa la keenay.)

3. Inta uu mashiinku ku jiro booskan kor-dhinaca-hooska ah, ku dhejitiiraristicmaalaya afarM8 x16dabool-madax boolal.Waxaad u baahan doontaa inaad furto laydhka foorarsiga si aad u geliso laba ka mid ah furayaashan.Hubi in tiirarka bidix iyo midig aanay is beddelin.Tiirarku waa sax haddii godadka kor u qaadista cagtu ay dibadda u soo jeedaan.

4. Ku dhejicagahatiirarkooda.(Dhammaadka leh godadka dunta dunta leh waa inay u jeedaan xagga dambe.) Afar isticmaalM10 x16badhanka-madax boolalcag walba.

5. Wareeg mashiinka ilaa caarada cagtu ay taabanayaan dhulka ka dibna, adigoo kaashanaya caawiye, mashiinka kor u qaad cagihiisa.

6. Ku rakib aM10 x25dabool-madax jebin isku dhufashocag walba gadaasheeda.Ku marooji furayaasha jackingka ilaa mashiinku ka xasilo.

7. Ku dhejishelfisticmaalaya afarM8 x16dabool-madax boolal.

8. Ku xidh fiilada-clip-ka dhexda dambe ee tiirka midig adigoo isticmaalaya anM6 x 10 Phillips-madax isku dhufasho.

9. Ku dhejisaxaarad(oo leh sariirta cinjirka ah) xagga dambe ee dhexe ee sariirta magnetka iyadoo la isticmaalayo saddexM8 x16dabool-madax boolal.

10. Ku rakib 4istaagid baararka, iyadoo la isticmaalayo laba boolal M8 x 17 bar kasta.Ku dheji Collar Joogsi ah oo ku dheji bar kasta oo dambe.

11. Ku dheji bidix iyo midigqaade gacanqabsixagga dambe ee usheeda dhexe ka muuqata dhinaca dambe ee tiirarka.Isticmaal midM8 x20dabool-madax boolalgacan kasta.

12. Si buuxda kor ugu rog alwaaxda foorarsan, oo ku xidhxamiliiyada oo miisaanka xagasha uu ku yaal booska saxda ah adoo isticmaalaya labaM8 x20dabool-madax boolal.Ku dheji gacanta kale ee booska bidix.

13. Ku rakib ajoojin cufangacanta midig oo si khafiif ah ugu dheji meel u dhow meesha sare ee gacanta.

14. Simbiriirixeexagal Tilmaame unuggacanta midig u gal.Ka saar furayaasha labada daraf ee dunta tilmaanta, ku dheji 2da gacmood, oo dib u adkee labada bilal.Fiiro gaar ah: Haddii boolalyaashan aan si fiican loo adkayn markaa habka beddelidda si sax ah uma shaqayn doono.

15. Ku rakib Footswitch-ka.Ka saar guddiga gelitaanka dambe (8 off M6 x 10 Phillips boolal madaxa).Geli fiilada-dhamaadka footswitch godka bartamaha guddiga oo geli godka firaaqada ah.Ku rakib block-ka kor-u-qaadista footswitch guddiga gelitaanka adigoo isticmaalaya laba boolal M6 x 30.

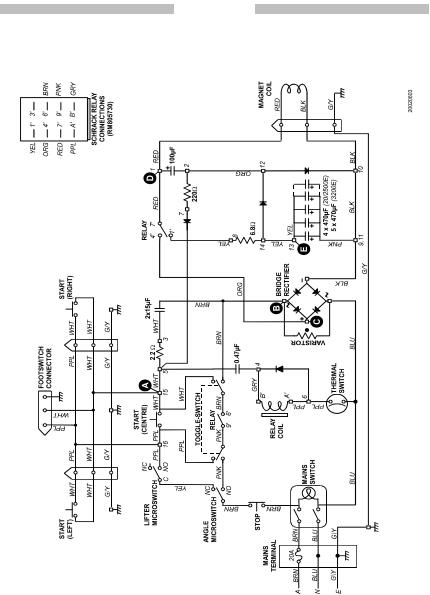

| Voltage Tijaabooyin | |||||

| AC | DC | ||||

| Barta tixraaca | Silig kasta oo buluug ah | Silig kasta oo MADOW | |||

| Barta tijaabada | A | B | C | D | E |

| Iftiin-ku-qabsiga xaalad | 240 V ac | 25 V ac | +25 V dc | +25 V dc | -300 V dc |

| FULL-xajin xaalad | 240 V ac | 240 V ac | +215 V dc | +215 V dc | -340 V dc |

(Iskirooyinkaan waxaa laga yaabaa in mar horeba si dabacsan loogu rakibay guddiga.) Dib u rakib guddiga gelitaanka .

16. Bolt ah mashiinka to ah dabaqaisticmaalaya labaM12 x60masonary boolal

(la keenay).Adigoo isticmaalaya qaniinyada 12 mm dhumucdiisuna waxay laba dalool, ugu yaraan 60 mm qoto dheer yihiin, iyada oo la sii marinayo godadka hore ee cag kasta.Geli biraha dhagaxa ah oo adkee nuts.Ogow:Haddii mishiinka loo isticmaalo foorarsiga cabbirka iftiinka oo keliya (illaa 1 mm) markaas lagama yaabo in loo baahdo in lagu xidho dhulka, si kastaba ha ahaatee foorarsi culus waa lagama maarmaan.

17.Ka saarcad difaacid daahanlaga soo bilaabo dusha sare ee mashiinka iyo dhinaca hoose ee xajinta.Walxaha ku haboon waa batrool ama basiin (basiin).

18.Dhigclampbaroo ku yaal baararka dambe ee mashiinka, oo horay u jiid si aad u hawlgeliso madaxyada biinanka (la soo celiyay) biinanka.Samee habka wax-qaadista adiga oo si adag dib ugu riixaya mid ka mid ah gacan-qaadashada ka dibna sii daa horay.

19.JDCBEND kaaga waa diyaar in la isticmaaloFadlan hadda akhri ah Hawlgalka Tilmaamaha.

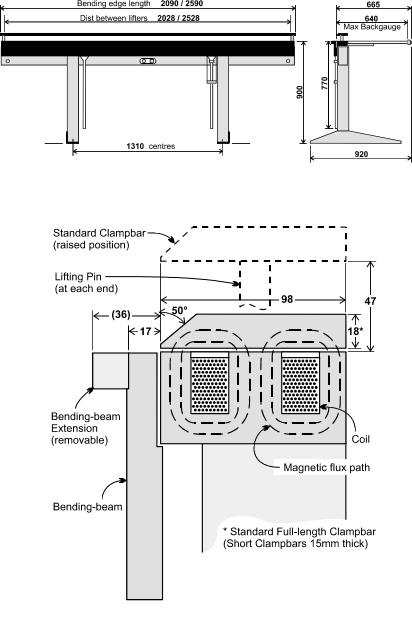

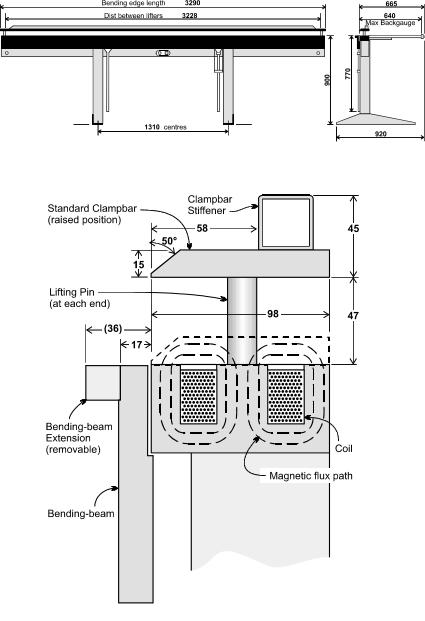

MAGACA AH AWOODDA Mashiinka Miisaanka

Qaabka 2000E: 2000 mm x 1.6 mm (6½ft x 16g) 270kg

Qaabka 2500E: 2500 mm x 1.6 mm (8ft x 16g) 315 kg

Qaabka 3200E: 3200 mm x 1.2 mm (10½ft x 18g) 380kg

CULUS XOOG

Isku geynta xoogga leh isku dhejinta dhererka buuxa ee caadiga ah:

| Qaabka 2000E: | 9 Tonne |

| Qaabka 2500E: | 12 Tonne |

| Qaabka 3200E: | 12 Tonne |

Koronto

1 Wajiga, 220/240 V AC

Hadda:

Qaabka 2000E: 12 Am

Qaabka 2500E: 16 Am

Qaabka 3200E: 16 Am

Wareegtada Xilka: 30%

Ilaalinta: kulaylka goynta, 70°C

Xakamaynta: badhanka bilawga ...xoogga hor-u-qabsiga

Laabicida beam microswitch ...xajin buuxda

Isku xidhka ...Badhanka bilawga iyo laydhka foorarsiga waa inay shaqeeyaan-

si sax ah isku xigxiga loo sameeyay si loo bilaabo xoog isku dhejin buuxda .

HINGES

Naqshad gaar ah oo aan xarun lahayn si ay u bixiso mashiin gebi ahaanba furan.

xagal wareeg: 180°

foorarsan CABIRKA

waxay u baahan tahay xoog qabsi badan .Xoog qabsi la'aanta badanaa waxay la xiriirtaa

labada boolal ee koofiyada M8 ee labada daraf ee shafka actuator ma noqon-

cidhiidhi .Haddi hawlgeliyaha uu wareego oo uu xajiyo OK laakiin wali ma sameeyo

dhagsii microswitch ka dibna waxay u baahan kartaa hagaajin.Si tan loo sameeyo marka hore

Mashiinka ka soo xir korontada ka dibna ka saar korontada

guddiga gelitaanka .

Barta jeedinta waxa lagu hagaajin karaa iyada oo la rogi karo biro dhaaftay

iyada oo loo marayo actuator .furka waa in la hagaajiyaa sida

beddel gujis marka cidhifka hoose ee laydhka foorarsigu dhaqaaqo

qiyaastii 4 mm.(Isku hagaajin la mid ah ayaa sidoo kale lagu gaari karaa foorarsi

gacanta mikroswitch.)

b) Haddii microswitch-ku aanu gujin ON iyo OFF inkasta oo qalabeeyaha uu si sax ah u shaqeynayo markaa furaha laftiisa ayaa laga yaabaa inuu ku dhex milmo oo wuxuu u baahan doonaa in la beddelo.

c) Haddii mashiinkaagu uu ku rakiban yahay furaha kaaliyaha markaa hubi in loo beddelay booska "caadiga ah".(Kaliya isku xidhka nalka ayaa la heli karaa haddii dabeedku ku jiro booska "AUX CLMP")

3. Isku dhufashada is OK laakiin Clampbars do maaha sii dayn Goorma ah mashiinka furayaasha

DAMN:

Tani waxay tusinaysaa guuldarada ku timaadda wareegga dib-u-dejinta garaaca wadnaha.The

Sababta ugu badan ayaa noqon doonta iska caabin koronto oo ah 6.8 Ω.Sidoo kale iska hubi

dhammaan diodes-yada iyo sidoo kale suurtogalnimada in ay ku dhegganaadaan xiriirada gudbinta.

4 . Mashiinka doono maaha foorarsi culus qiyaas xaashida:

a) Hubi in shaqadu ku dhex jirto qeexida mishiinka .Marka loo eego-

ticular note in loogu talagalay 1.6 mm (16 cabbir) foorarsiga ahkordhin baar

waa in lagu rakibaa laydhka foorarsiga iyo in ballaca dibnaha ugu yar yahay

30 mm.Tani waxay ka dhigan tahay in ugu yaraan 30 mm walxo ay tahay inay soo saaraan

laga bilaabo cidhifka qalooca ee xajinta .(Tani waxay khusaysaa labada aluminium-

ium iyo birta.)

(Bishimaha cidhiidhiga ah waa suurtogal haddii laabladu aanay ahayn dhererka buuxa ee naaska-

shiine.)

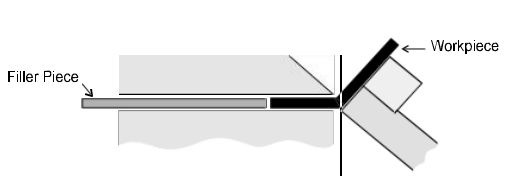

b) Sidoo kale haddi xuubka shaqadu aanu buuxin booska ka hooseeya xajinta

markaas ayaa laga yaabaa in wax qabadku saameeyo .Natiijooyinka ugu wanaagsan had iyo jeer buuxi

meel bannaan oo ka hooseysa xajinta oo leh gabal bir ah oo dhumucdiisuna ay la mid tahay

sida workpiece ah.(Si aad u xajinayso birlabeedka ugu fiican qaybta buuxintu waa inay

noqonbirxitaa haddii qalabka shaqada uusan ahayn bir.)

Tani sidoo kale waa habka ugu wanaagsan ee loo isticmaalo haddii loo baahdo in la sameeyo faruuryo cidhiidhi ah

on the workpiece .

... QAABKA ...

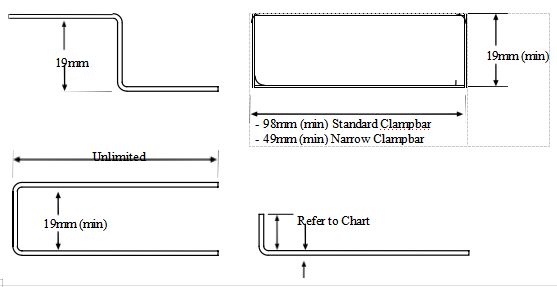

foorarsan AWOODDA

(Marka la isticmaalayo xajinta dhererka caadiga ah -bar si aad u laaloosho gabal shaqo dhererkeedu dhan yahay)

| ALAAB (wax-soosaar/ walbahaarka ugu dambeeya) | DHULKA | BALAALO FARUUR (ugu yaraan) | LABAAD RADIUS (caadi) |

| Fudud-bir (250/320 MPa) | 1.6 mm | 30 mm* | 3.5 mm |

| 1.2 mm | 15 mm | 2.2 mm | |

| 1.0 mm | 10 mm | 1.5 mm | |

| Aluminiumm Fasalka 5005 H34 (140/160 MPa) | 1.6 mm | 30 mm* | 1.8 mm |

| 1.2 mm | 15 mm | 1.2 mm | |

| 1.0 mm | 10 mm | 1.0 mm | |

| Aan lahayn Birta Fasalada 304, 316 (210/600 MPa) | 1.0 mm | 30 mm* | 3.5 mm |

| 0.9 mm | 15 mm | 3.0 mm | |

| 0.8 mm | 10 mm | 1.8 mm |

* Iyada oo bar-dheeraynta lagu rakibay laydhka foorarsiga.

GAABAN CULUS-BAR SET

Dhererka:: 25, 38, 52, 70, 140, 280, 597, 1160 mm

Dhammaan cabbirrada (marka laga reebo 597 mm & 1160 mm) waa la isku dhejin karaa si ay u sameeyaan gees foorarsi gudaha 25 mm dherer kasta oo la rabo ilaa 575 mm.

LAGU QABTAY CLMPBAR

Loo keenay sidii ikhtiyaar dheeraad ah oo loogu talagalay samaynta digsiyada gacmeed .Leh set gaar ah oo ah8 mm ballaaran by40mm qoto dheer * boosaska bixiya samayntadhammaanCabbirrada saxanka ee u dhexeeya 15 ilaa 1265 mm

* Si aad u hesho saxaarad qoto dheer isticmaal set-bar gaaban

Sida ugu fudud ee lagu xallin karo dhibaatooyinka korantada waa in la dalbado qalab koronto oo beddela soo saaraha .Tan waxaa lagu soo iibsadaa qaab beddelaad ah sidaas darteedna waa mid aad u qiimo jaban .Kahor intaadan dirin moduleka beddelka waxaad jeclaan kartaa inaad hubiso kuwan soo socda:

1. Mashiinka sameeyo maaha hawlgeli at dhammaan:

a) Hubi in korantadu ay ka heli karto mishiinka adiga oo eegaya nalka duuliyaha ee shid/damisan

b) Haddii korontadu ay jirto balse mishiinku weli dhintay balse uu dareemayo kuleyl aad u kulul ka dib waxaa dhici karta in kulaylku goynayo.Xaaladdan oo kale sug ilaa mashiinku qaboojiyo (ku saabsan½ saacad) ka dibna isku day mar kale.

c) Isku xidhka bilawga labada gacmood wuxuu u baahan yahay in badhanka START la riixoka horgacanta ayaa la jiidayaa .Haddii gacanta la jiidomarka horemarkaa mashiinku ma shaqayn doono .Sidoo kale waxa dhici karta in laydhka foorarsiga ahi dhaqaaqo (ama uu ku dhaco) si ku filan si uu ugu shaqeeyo "angle mi-croswitch" ka hor inta aan la riixin badhanka START .Haddii ay tani dhacdo iska hubi in gacanta si buuxda dib loogu riixay marka hore.Haddii tani ay tahay dhibaato joogto ah markaas waxay muujinaysaa in barta-danka ee mishiinka microswitch u baahan yahay hagaajin (hoos eeg) .

d) Suurtagalnimada kale ayaa ah in badhanka START uu khalad yahay.Eeg haddii mishiinka lagu bilaabi karo mid ka mid ah badhamada START ee beddelka ah ama lugaha.

e) Sidoo kale hubi xidhiidhiyaha ku xidhaya moduleka korantada iyo gariiradda magnetka.

f) Haddi xajintu shaqayn waydo laakin xajintu hoos u dhacaysosii daynee badhanka START ka dib tani waxay muujinaysaa in 15 microfarad capacitor uu khaldan yahay oo u baahan doono in la beddelo.

g) Haddii mishiinku uu afuufo fiyuusyada dibadda ama uu ku safro wareegyada wareegga marka la shaqeeyo markaas sababta ugu badan waa buundada-hagaajinta.

2. Iftiin xajin shaqeeya laakiin buuxa xajin sameeyo maaha:

a) Hubi in "Angle Microswtich" si sax ah loo dhaqaajiyay.

[Tani beddelo is qalay by a afar geesle naxaas gabal kaas is ku lifaaqan to

ah xagal tilmaamaya farsamaynta. Goorma ah xamili is jiiday ah foorarsanaan qoryo meerto kaas wax siin a wareeg to ah naxaas firfircoone.

The ac- macalin in leexo shaqeeya a mikroswitch gudaha ah koronto shirka.]

Ka soo saar gacanta oo gudaha .Waa inaad awood u yeelatid inaad maqasho mikroswitch-ka oo gujinaya ON iyo Off

Haddii daaruhu uusan taxin ON iyo OFF ka dibna u lul laydhka foorarsiga midigta sare si qalabka naxaasta loo arko .U rog rog rogmada kor iyo hoos .Dhaqdhaqaaquhu waa in uu u rogmadaa si uu uga jawaabo laydhka foorarsan (ilaa uu ku qabsado joogsigiisa) .Haddii aysan taasi dhicin markaas way dhici kartaa

SHAQAYNTA Dusha sare

Haddii sagxadaha shaqada ee qaawan ee mishiinku noqdaan kuwo daxalaystay, wasakhoobay ama biyo xidheen.

da'da, waxa laga yaabaa in si sahal ah loo hagaajiyo.Wixii burooyin ah ee kor loo qaado waa in la xereeyaa

biyo raaci, oo dusha sare lagu xoqay warqad P200 emery ah.Ugu dambeyntii mari buufin-

Ka hortagga miridhku sida CRC 5.56 ama RP7 .

HINGE SUUQAYN

Haddii galka xaashida ee Jdcbend TM si joogto ah loo isticmaalo, ka dibna dufan ama saliidda

jilbaha hal mar bishii.Haddii mishiinka la isticmaalo wax ka yar, markaas waxa laga yaabaa in la dubo

si joogta ah.

Godad saliidda waxaa lagu bixiyaa labada lugood ee saxan hinge ugu weyn, iyo ah

dusha sare ee wareega ee qaybta qaybta waa in sidoo kale lagu dhejiyaa saliid

waa.

ADJUSTERS

Qaboojiyaha cidhifyada clampbar-ku waa inay xakameeyaan oggolaanshaha

dhumucdiisuna waxay ka mid ah workpiece u dhexeeya laab-laabashada iyo dogob foorarsan.

Ogow in madaxyada boolalku ay u qaybsan yihiin 3 mid, laba iyo saddex xarun

calaamadaha pop.Calaamadahani waa tixraac faa'iido leh oo loogu talagalay ku-noqoshada dejinta ee clampbar.

Haddii boolal-hagaajinta labadooduba loo dejiyey si ay calaamadda pop-ka keliya u sarrayso markaas waa

farqiga foorarsiga wuxuu noqon doonaa qiyaastii 1 mm.

| MODEL | Taxane NO. | TAARIIKHDA |

| DHULKA XIDHIIDHYADA Cabbira caabbinta dhexda dhexe ee ku xidha pin dhulka ilaa jidhka magnetka.... Koronto KARANTIIL Megger laga bilaabo gariiradda ilaa jirka magnetka............................................. MIN/MAX Sahayda Voltage IMTIXAANKA At 260v: Pre-clamp ....xajin buuxda ....sii dayn ............................ At 200v: Pre-clamp ....sii dayn ................................................. Isku-duubista ka hor ....xajin buuxda ....sii dayn ............................. INTERLOCK TIXDA Markaad korontadu shidantahay, jiid HANDLE, dabadeed taabo badhanka START .

MANSAHA CABLE PLUG Hubi in furgu yahay nooca/ cabbirka saxda ah………………………………………. FOOTSWITCHFootswitch ma hawlgeliyaa isku xidhka iftiinka?…… . rog-ON/DAMN Xaglo Dhaqdhaqaaqa leexinta Beam si aad u dhaqaajiso xirid buuxda, lagu cabbiray xagga hoose ee laydhka foorarsiga .(4 mm ilaa 6 mm) .............. U laabo mashiinka daminta.Dib u cabbir ka 90° .(Waa in ay ahaataa inta u dhaxaysa 15°+5°)...................... | ohm

mm deg |

XAGAL Miisaanka

Wax-ku-akhrinta cidhifka Tusiyaha marka foorarsiga laydhka la dhigayo

| MAGNET JIRKA Toosanaanta dusha sare, oo ay weheliso cirifka hore (max weecasho = 0.5 mm) ..................................... Fiican ee dusha sare, oo dhan tiirarka (max weecasho = 0.1 mm) ..................................... foorarsan BEAM Toosanaanta oogada shaqada (max weecasho =0 .25 mm) ........ Isku toosinta bar-kordhinta (max weecasho = 0.25 mm) ............. [Ogow: Ku tijaabi toosnaanta cidhif toosan oo qumman.] |

| mm mm mm mm |

Hubinta THE SAX AH OF KAAGA MAKIINKA

Dhammaan sagxadaha shaqada ee Jdcbend waxaa loo soo saaray inay toosan yihiin oo siman ilaa 0.2 mm gudaha dhererka mashiinka.

Qodobbada ugu muhiimsan waa:

11 .toosnaanta dusha shaqada ee laydhka foorarsiga,

2018-03-21toosnaanta cidhifka qalooca ee clampbar, iyo

3 .isbarbar yaaca labadan saqaf .

Sagxadahaas waxa lagu eegi karaa cidhif toosan oo sax ah laakiin hab kale oo wanaagsan oo wax lagu hubiyo ayaa ah in dusha la isu tixraaco .Si tan loo sameeyo:

11 .U lul laydhka foorarsiga ilaa 90° oo ku hay halkaas.(Albaabka waxa lagu xidhi karaa booskan iyada oo la geliyo kolaj-joojin dhabarka ah ee dhabarka lagu dhejiyo xagasha xagasha ee gacanta) .

2018-03-21U fiirso farqiga u dhexeeya cidhifka foorarsiga ee birta xajinta iyo dusha shaqada ee laydhka foorarsiga.Isticmaalka isku-habayayaasha xajinta waxay dejiyaan farqigan ilaa 1 mm dhamaad kasta (isticmaal gabal xaashi ah oo bir ah, ama cabirka dareenka) .

Hubi in faraqa uu isku mid yahay inta lagu jiro xajinta.Kala duwanaanshuhu waa inuu gudaha ku jiraa±0.2mm.Taasi waa farqiga waa inuusan dhaafin 1.2 mm waana inuusan ka yarayn 0.8 mm.(Haddii hagaajinayaashu aysan isku si u akhriyin dhamaad kasta ka dibna dib u deji sida lagu qeexay hoos-u-dayactirka) .

Xusuusin:

a.Toosnimada xajinta sida lagu arkay sare u kaca (laga bilaabo xagga hore) muhiim maaha maxaa yeelay tani waxay ku soo baxaysaa xajin birlab ah isla marka mishiinka la furo.

b.Farqiga u dhexeeya laydhka foorarsiga iyo jidhka birlabeedka (sida lagu arkay qorshaha iyada oo lafo foorarsigu ku jiro booska guriga) caadiyan waa 2 ilaa 3 mm.Farqigani waamaahadhinaca shaqada ee mishiinka oo ma saameynayso saxnaanta foorarsiga.

c.Jdcbend-ku waxa uu soo saari karaa laalaabka fiiqan ee cabirrada dhuuban iyo walxaha aan birta ahayn sida aluminium iyo naxaasta.Si kastaba ha ahaatee cabbirada dhumuc weyn ee birta iyo birta aan la taaban karin ha filanin inaad gaadho laab fiiqan

(eeg faahfaahinta).

d.Isku mid ahaanshaha laabashada cabbirada dhumuc weyn ayaa lagu wanaajin karaa iyadoo la isticmaalo qaybo ka mid ah qalabka shaqada si loo buuxiyo qaybaha aan la isticmaalin ee ku hoos jira clampbar.

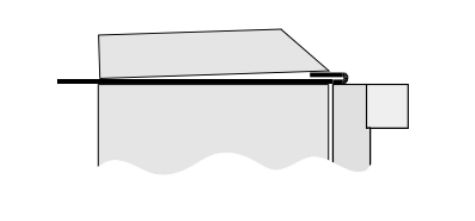

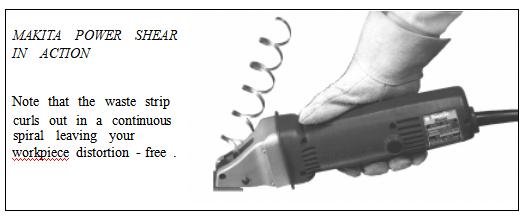

AWOODDA SHARE (Ikhtiyaar ah qalabayn)

TILMAAMAHA FOR ADEEGSIGA THE SHARE:

Xiritaanka awoodda (oo ku salaysan Makita Model JS 1660) waxay bixisaa hab loogu talagalay

goynta xaashida si ay qallooc yar uga hadho

workpiece .Tani waa suurtogal sababtoo ah xiiridu waxay soo saartaa xariijimaha qashinka, qiyaastii 4

ballac mm, iyo inta badan qallooca ku jira xaashida xiirida ayaa tan gala

xariijimaha qashinka.Isticmaalka Jdcbend xiirta waxa lagu rakibay qalab gaar ah

hagaha magnetic.

Shearku si fiican ayuu u shaqeeyaa marka lagu daro Folder Sheetmetal Jdcbend;ah

Jdcbend waxay bixisaa labada hab lagu hayo workpiece go'an marka la gooyo iyo

sidoo kale hab lagu hago qalabka si goyn aad u toosan ay suurtagal tahay.Goyn kasta

dhererka waxaa lagu maarayn karaa bir ilaa 1.6 mm qaro weyn ama aluminium ilaa 2 mm qaro weyn.

Si aad u isticmaashid qalabka marka hore dhig xaashida birta birta ah ee ka hooseysa clampbar ee Jdcbend

oo meel dhig si xariiqda goynta ay tahay mid sax ah1 mmxagga hore ee cidhifka ah

Laacida Beam.

Beddelka beddelka lagu calaamadiyay"CAADIGA / AUX CLAMP”waxaa laga heli doonaa agtiisa

Daar/Dami ugu weynTan u beddel booska AUX CLMP si aad u qabato

workpiece si adag booska.

... KORMEERKA XAASHI

UGU WEYN CLMPBAR

Toosanaanta gees-laabashada (max weecasho = 0.25 mm) ...........

Dhererka wiishka (iyada oo gacmaha kor loo qaado) (min 47 mm) ..................

Biinanka ma soo daa marka habka wax qaadista la xiro?..........

Iyada oo hagayaasha lagu dejiyay "1" iyo laydhka foorarsiga oo ah 90 °

waa qaloocidabarbar socdaku, iyo1 mmka, beam?.........Laydhka foorarsiga ee 90°, ma la hagaajin karaa xajinta

hore u siitaaboiyo gadaal by2 mm ?...................................

HINGES

Hubi in saliidda lagu shubo biraha iyo baloogyada qaybta..........

Hubi in hindhisyadu u wareegaan 180° si xor ah oo habsami leh.........

Hubi xiniinyahabiinankasameemaahameerto oo la helo ............

Ma la xidhay lowska xajinta?...............................

Dhig xiirta dhanka midig ee Jdcbend oo hubi in magnetic

lifaaqa hagaha waxa uu ku hawlan yahay cidhifka hore ee Laacidda Beam.Bilow awoodda

xiirid ka dibna si siman u riix ilaa goynta la dhammeeyo.

Xusuusin:

11 .Si loo helo wax qabad wanaagsan, nadiifinta daabka waa in la hagaajiyaa si ay ugu habboonaato dhumucda alaabta la jarayo.Fadlan akhri tilmaamaha Makita ee lagu soo daray xiirta JS1660.

2018-03-21Haddii xiiridu aanay si xor ah u goyn iska hubi in baaluqyadu fiiqan yihiin.

UGU WEYN CLMPBAR

Toosanaanta gees-laabashada (max weecasho = 0.25 mm) ...........

Dhererka wiishka (iyada oo gacmaha kor loo qaado) (min 47 mm) ..................

Biinanka ma soo daa marka habka wax qaadista la xiro?..........

Iyada oo hagayaasha lagu dejiyay "1" iyo laydhka foorarsiga oo ah 90 °

waa qaloocidabarbar socdaku, iyo1 mmka, beam?.........Laydhka foorarsiga ee 90°, ma la hagaajin karaa xajinta

hore u siitaaboiyo gadaal by2 mm ?...................................

HINGES

Hubi in saliidda lagu shubo biraha iyo baloogyada qaybta..........

Hubi in hindhisyadu u wareegaan 180° si xor ah oo habsami leh.........

Hubi xiniinyahabiinankasameemaahameerto oo la helo ............

Ma la xidhay lowska xajinta?...............................

Dhig xiirta dhanka midig ee Jdcbend oo hubi in magnetic

lifaaqa hagaha waxa uu ku hawlan yahay cidhifka hore ee Laacidda Beam.Bilow awoodda

xiirid ka dibna si siman u riix ilaa goynta la dhammeeyo.

Xusuusin:

11 .Si loo helo wax qabad wanaagsan, nadiifinta daabka waa in la hagaajiyaa si ay ugu habboonaato dhumucda alaabta la jarayo.Fadlan akhri tilmaamaha Makita ee lagu soo daray xiirta JS1660.

2018-03-21Haddii xiiridu aanay si xor ah u goyn iska hubi in baaluqyadu fiiqan yihiin.

foorarsan TIJAAB

(Qoddobka ugu sarreeya ee loo leexiyo 90°, ugu yaraan korantada sahayda.)

Dhumucda gabalka tijaabada birta........mm, Dhererka laabta ...........

Ballaca dibnaha ............................mm, leexiyo raadiyaha ...........

Labbiska xagasha leexinta ( weecasho ugu badan = 2°) ..................

LHAABIIL

Hubi sida ay u kala caddahay, ku dhegganaanshaha mashiinka iyo toosinta saxda ah.

Saxeexa Magaca & Taxanaha No............Digniinta Clampbar .......

Digniin koronto ..................Beddel calaamadaynta..........

Cajaladda badbaadada ee lugaha hore ..........

DHAMEYSO

Hubi nadaafadda, ka madax bannaanida miridhku, ceebaha iwm.....................

SHAQAYSIINTA TILMAAMAHA:

WAQOONSIIN

Galka xaashida ee Jdcbend waxa uu samayn karaa isugeyn xoog isku dhufasho ah oo dhowr tan ah

(fiiri SIYAASADDA).Waxay ku qalabaysan tahay 2 badbaado oo is-dhexgal ah: Midda koowaad waxay u baahan tahay

in habka isku-xidhka ka-hor-istaagga badbaadada leh uu ku hawlan yahay ka hor inta aan si buuxda loo hawlgelin.

Midda labaadna waxay u baahan tahay in xajintu hoos loo dhigo ilaa 5 mm gudahood

sariirta ka hor inta uusan magnetku shidin.Qufulyadaani waxay caawiyaan hubinta taas

faraha si badheedh ah looguma qaban karo clampbar hoosteeda marka electro-magnetic

xajin ayaa lagu dabaqaa.

Si kastaba ha ahaatee,it is inta badan muhiim ah in kaliya mid hawlwadeen xakamaynta ah mashiinkawaana tahay

dhaqan wanaagsan simarnaFarahaaga geli meesha lagu xidho.

CAADIGA AH foorarsan

Hubi in ay korontadu shidantahay meesha korontada laga bixiyo iyo daminta/damida mishiinka

shiinaha .Isku-xidhka dhererka dhererkiisu dhan yahay waa inuu saarnaadaa mishiinka wax qaadaya

biinanka soo jiidaya godadka cidhifyada clampbarka.

Haddii biinanka wax lagu qaado ay hoos xiran yihiin ka dib sii daa adiga oo si adag dib ugu riixaya

gacanta (ku yaal mashiinka hoostiisa u dhow tiir kasta) iyo sii deynta

waadhadhka .Tani waa inay xoogaa sare u qaaddaa xajinta.

1 . hagaaji waayo workpiece dhumucdiisunaadiga oo isku rogaya 2da boolal ee cidhifka dambe ee xajinta.Si aad u hubiso nadiifinta kor u qaad laydhka foorarsiga ilaa 90° oo u fiirso faraqa u dhexeeya cidhifka foorarsiga ee xajinta iyo dusha sare ee laydhka foorarsiga .(Natiijooyinka ugu wanaagsan ee farqiga u dhexeeya cidhifka clampbar iyo dusha sare ee laydhka foorarsiga waa in la dejiyaa in ka yar dhumucda birta la leexiyo.)

2 . Geli ah workpiecehoostiisa clampbar .(Dharka dhabarka la hagaajin karo ayaa la dejin karaa haddii loo baahdo.)

3 . Hoose ah clampbar gal ah workpiece.Tan waxaa lagu samayn karaa gacan-qaadista ama adigoo si fudud hoos u riixaya xajinta.

Fiiro gaar ah: Isku-xidhka ayaa hubinaya in mashiinku aanu shidmi doonin ilaa tan

clampbar waxa lagu soo dejiyey ilaa 5 mm gudahooda ka koraysa sariirta oogada .Haddii ay

clampbar si ku filan hoos looguma dhigi karo, tusaale.sababtoo ah waxay ku nasanaysaa a

Qalabka shaqada ee xidhan, ka dibna qufulka waxa lagu shaqayn karaa iyadoo hoos loo xidhayo

habka qaadista .(Si adag dib ugu riix mid ka mid ah gacmaha wax-qaadista.)

4 . Riix iyo haynmid ka mid ah 3 badhamada START cagaaranorku shaqee lugta - beddelka .Tani waxay khusaysaa xoogga hore ee isku dhejinta .

5 .Gacantaada kale ku jiid mid ka mid ah gacan-ku-laabashada .Tani waxay kicisaa mikroswitch kaas oo hadda sababi doona in si buuxda loo xidho.Badhanka START (ama footswitch) waa in hadda la sii daayaa.

6 .Bilow foorarsiga adigoo soo jiidaya labada gacan ilaa inta la rabo la laalaadinayo -

SAMEYNAYA TAYSIISKA (ADEEGSIGA LAGU QABTAY CLMPBAR)

Clampbar-ka Slotted, marka la keeno, wuxuu ku habboon yahay samaynta saxaarad-gacmeedka iyo digsiyada si degdeg ah oo sax ah.Faa'iidooyinka clampbar-ka-xiran ee ka sarreeya xirmooyinka gaaban ee dhejiska ee samaynta saxarada ayaa ah in cidhifka foorarsiga uu yahay mid otomaatig ah - cally oo ku habboon mashiinka intiisa kale, iyo clampbar wuxuu si toos ah u qaadayaa si uu u fududeeyo gelinta ama ka saarista qalabka shaqada.Marnaba-wax-yar, xargaha gaaban ayaa loo isticmaali karaa in lagu sameeyo saxaarad qoto dheer oo aan xadidnayn, dabcan, way ku fiican yihiin samaynta qaabab isku dhafan.

Isticmaalka, boosasku waxay u dhigmaan faraqa u dhexeeya faraha sanduuqa caadiga ah & mashiinka laalaabida digsiga.Balaadhka boosasku waa sida in labada boosba ay ku haboonaan doonaan saxaarad ka badan 10 mm, tirada iyo meelaha boosasku waa sidaaswaayo dhammaan cabbirrada of saxaarad , mar walba waxaa la heli karaa laba boos oo ku haboon.(Xajmiga saxaarad ee ugu gaaban iyo kan ugu dheer ee xajmigu ku dheggan yahay waxay ku hoos taxan yihiin SPECIFICATIONS.)

Si aad u laabiso saxaarad-gacmeed:

11 .Isku laab labada dhinac ee hore ee iska soo horjeeda iyo koonaha tabsiyada adigoo isticmaalaya xajinta xajinta laakiin iska indha tiraya joogitaanka boosaska.Boodhadhkani wax saamayn ah oo la arki karo kuma yeelan doonaan laalaabyada dhammaatay.

2018-03-21Hadda dooro laba boos oo u dhexeeya kuwaas oo la isku laabi karo labada dhinac ee soo hadhay.Runtii tani waa mid aad u fudud oo la yaab leh oo degdeg ah .Kaliya saf dhinaca bidix ee saxaaradda qayb laga sameeyay oo leh booska bidix oo arag haddii uu jiro boos dhinaca midig ah oo lagu riixayo;Haddaysan ahayn, jiid saxanka ilaa dhinaca bidix ka yahay booska xiga oo isku day mar kale.Caadi ahaan, waxay qaadataa ilaa 4 isku day oo kale si loo helo laba boos oo ku habboon.

3 .Ugu dambeyntii, cidhifka saxaarada oo hoos yimaada xajinta iyo inta u dhaxaysa labada boos ee la doortay, laabi dhinacyada soo hadhay.Dhinacyadii hore loo sameeyay waxay galayaan boosaska la doortay marka laalaabyada ugu dambeeya la dhammeeyo.

Dhererka saxaaradda oo ku dhow ilaa iyo inta xajinta waxa laga yaabaa inay lagama maarmaan noqoto in la isticmaalo hal daraf ee xajinta meel bannaan oo bannaan ah .

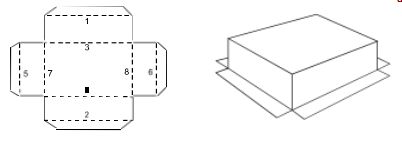

... SANDUUQYADA

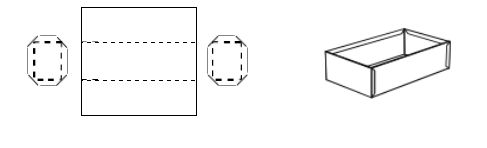

Carraray Sanduuqa leh Geeska Tabs

Markaad samaynayso sanduuq bannaanka ka flanged leh oo leh tab geeso leh oo aan la isticmaalin

Qaybaha dhamaadka kala duwan, waa muhiim in la sameeyo laalaabyada isku xigxiga saxda ah.

11 .U diyaari meel bannaan oo leh tabsyo gees ah oo loo habeeyey sida muuqata.

2018-03-21Hal daraf ee xajinta dhererka dhererka buuxa, samee dhammaan laalaabka tab "A" ilaa 90° .Way fiicantahay in tan la sameeyo iyada oo la geliyo tab-ka-xajinta hoostiisa.

3 .Isla dhamaadka-dhererka xajinta, samee laalaabka "B"to45°kaliya .Sidan ku samee adigoo gelinaya dhinaca sanduuqa, halkii aad ka geli lahayd sanduuqa hoose ee sanduuqa, hoosta xajinta.

4 .Dhamaadka kale ee xajinta dhererka dhererka, samee laalaabka flange "C" ilaa 90°.

5 .Adigoo isticmaalaya xirmooyinka gaaban ee ku habboon, dhammaystir laalaabka "B" ilaa 90°.

6 .Ku biir geesaha .

Xusuusnow in sanduuqyada qoto dheer ay u fiicnaan karto in sanduuqa lagu sameeyo gooni gooni ah

gabal dhamaadka .

... HAWLGALKA

xagal baa la gaadhay .(shaqo qaloocis culus waxaa loo baahan doonaa kaaliyaha .) xagasha alwaaxdu si joogto ah ayaa loogu tilmaamaa miisan qalin jabiyay oo ku yaala dhinaca hore ee gacanta midigta .Caadi ahaan waa lagama maarmaan in la foorarsado dhawr darajo oo ka baxsan xagasha qaloocinta la rabo si loogu oggolaado dhabarka gu'ga alaabta foorarsan.

Shaqada soo noqnoqda joogsiga waxaa la dhigi karaa xagasha la rabo .Mashiinku wuu dami doonaa marka dhaq-dhaqaaqa laydhka foorarsiga la rogo .

Wakhtiga la damiyo wareegga korantada ee mishiinku waxa uu soo daayaa garaaca rogaal celiska ah ee hadda socda iyada oo loo marayo electro-magnet kaas oo meesha ka saaraya inta badan magnetism-ka haraaga ah oo u ogolaanaya in si degdeg ah loo sii daayo clampbar .

Markaad ka saartid qalabka shaqada, wax yar oo kor u kaca ayaa kor u qaadi doona xajinta si ku filan gelinta qalabka shaqada ee soo socota.(Haddii loo baahan yahay in kor loo qaado xajinta xajinta markaa tan si fudud ayaa lagu dhammeeyaa iyada oo la isticmaalayo mid ka mid ah gacan-qaadashada.)

CAUTION

• Si looga fogaado khatarta ah in la dhaawaco cidhifka qalooca ee clampbar ama in la ilko korka sare ee jidhka birlabta,do maaha dhig yar walxaha un- der ah clampbar.Dhererka foorarsiga ugu yar ee lagu taliyey iyadoo la adeegsanayo xajinta caadiga ah waa 15 mm, marka laga reebo marka qaybta shaqada ay aad u dhuuban tahay ama jilicsan tahay.

• Awooda isku dhufashada ee birlabku way yaraataa marka ay kulushahay .Sidaa darteed si aad u hesho waxqabadka ugu fiicancodsan xajin waayo no dheer ka badan is lagama maarmaan ahsi aad u qaloociso .

ADEEGSIGA THE BACKSTOPS

Dhabarka dambe ayaa faa'iido leh marka tiro badan oo foorarsi ah ay tahay in la sameeyo dhammaantood kuwaas oo isku mid ah u jira cidhifka shaqada .Marka dhabarka joogsigu si sax ah loo dhigo tiro kasta oo foorarsi ah ayaa la samayn karaa iyada oo aan loo baahnayn wax cabbira ama calaamadaynta shaqada.

Caadiyan joogsiyada dambe waxa loo isticmaali lahaa bir iyaga ka gees ah si ay u sameeyaan dusha dheer oo lagu tixraaco cidhifka shaqada .Ma jiraan baarar gaar ah oo la bixiyay laakiin gabalka dheeriga ah ee ka soo baxa laydhka foorarsiga ayaa la isticmaali karaa haddii baarka kale ee ku habboon la waayo.

FIIRO GAAR AH: Haddii loo baahan yahay in la dhigo dhabarka dambehoostoodaclampbar-ka, ka dib tan waxaa lagu samayn karaa iyadoo la isticmaalayo bir bir ah oo la mid ah dhumucda shaqada, iyadoo lala kaashanayo dhabarka dambe.

laablaaban A FARUURTA (HEM)

Farsamada loo isticmaalo bushimaha laalaabo waxay kuxirantahay dhumucda shaqada iyo

ilaa xad, dhererkiisa iyo ballaadhkiisa.

khafiif ah Qalabka shaqada (up to 0.8 mm)

11 .Ku sii wad sida foorarsiga caadiga ah laakiin sii wad foorarka ilaa inta suurtogalka ah (135°) .

2018-03-21Ka saar bar-xajinta oo uga tag qaybta shaqada ee mashiinka laakiin u dhaqaaq xagga dambe ilaa 10 mm.Hadda luxul bararka foorarsiga si aad dibinta u cadaadiso .(isku-qabsiga looma baahna in la mariyo) .[Fiiro gaar ah: Ha isku dayin inaad ku samayso bishimo cidhiidhi ah oo ku yaal qaybo-shaqo qaro weyn].

3 .Iyada oo leh qaybo-shaqo oo khafiif ah, iyo/ama meesha aan bushimuhu aad u cidhiidhi ahayn, ayaa ka sii daran

fidsanaanta balaastigga ah waxaa lagu gaari karaa iyadoo la raacayo xajinta magnetka

kaliya:

... SANDUUQYADA ...

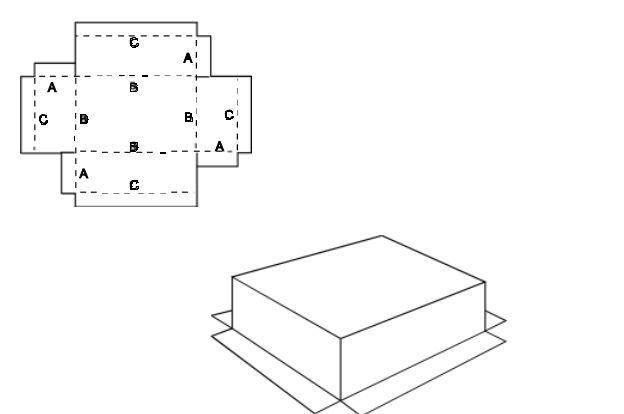

Sanduuqyada leh kala saar dhamaado

Sanduuqa lagu sameeyay cidhifyo gaar ah ayaa leh faa'iidooyin dhowr ah:

- waxay kaydisaa alaabta haddii sanduuqu leeyahay dhinacyo qoto dheer,

- uma baahnid cidhifyo gees ah,

- dhammaan goynta waxaa lagu samayn karaa guillotine;

- Laalaabyada oo dhan waxaa lagu samayn karaa clampbar dhererkiisu dhan yahay oo cad;iyo qaar ka mid ah cilladaha:

- Laabyo badan waa in la sameeyaa;

- geeso badan waa in lagu biiraa, iyo

- geeso badan oo bir ah iyo xirmooyin ayaa muujinaya sanduuqa la dhammeeyay.

Samaynta santuuqa noocan ahi waa mid toosan oo dhererka dhererkiisu dhan yahay waxa loo isticmaali karaa laalaabka oo dhan.

11 .U diyaari meelaha banaan sida hoos ku cad .

2018-03-21Marka hore ku samee afarta laalaab ee shaqada ugu weyn.

3 .Marka xigta, samee 4 geesood ee gabal kasta oo dhamaadka ah.Mid kasta oo ka mid ah laalaabyadan, geli cidhifka cidhiidhiga ah ee gabal dhamaadka hoostiisa.

4 .Ku biir sanduuqa si wadajir ah .

Carraray sanduuqyada leh cad geesaha

Sanduuqyada geesaha leh ee geesaha ka baxsan waa sahlan tahay in la sameeyo haddii dhererka iyo ballaca ay ka weyn yihiin ballaca clampbar ee 98 mm.Samaynta sanaadiiqda leh geesaha ka baxsan waxay la xidhiidha samaynta QAYBAHA TOP-HAT (oo lagu sifeeyay qayb danbe - arag nuxurka) .

4 .U diyaari meesha bannaan .

5 .Adigoo isticmaalaya xajinta dhererka dhererka buuxa, samee laalaabyada 1, 2, 3 & 4.

6 .Geli flange ka hoostiisa xajinta si aad u sameyso laalaab 5, ka dibna laabi 6.

7 .Isticmaalka

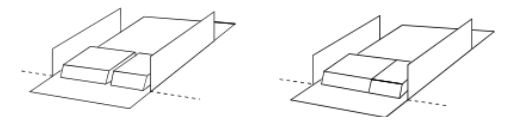

SAMEYNTA SANDUUQYADA (ADEEGSIGA GAABAN CLAMPBARS)

Waxaa jira siyaabo badan oo loo dhigo sanduuqyada iyo habab badan oo la iskulaabi karo.Jdcbend-ku wuxuu ku habboon yahay samaynta sanduuqyo, gaar ahaan kuwa kakan, sababta oo ah kala-duwanaanshaha isticmaalka xirmooyinka gaagaaban si loo sameeyo laalaabyo oo aanay caqabad ku ahayn laalaabyadii hore.

Cad Sanduuqyada

1. Samee labada laab ee hore adigoo isticmaalaya xajinta dheer sida foorarsiga caadiga ah.

Dooro mid ama ka badan oo ka mid ah xirmooyinka gaagaaban iyo booska sida muuqata.(Ma aha lagama maarmaan in la sameeyo dhererka saxda ah sababtoo ah leexintu waxay qaadi doontaa nusqaamaha ugu yaraan20 mminta u dhaxaysa xirmooyinka.)

Laacida ilaa 70mm dhererka, kaliya dooro xajinta xajinta ugu weyn ee ku haboon.Dhererka dheer waxaa laga yaabaa inay lagama maarmaan noqoto in la isticmaalo dhowr xabbo oo xajin ah.Kaliya dooro xejinta ugu dheer ee ku haboon, ka dibna kan ugu dheer ee ku haboonaan doona faraqa soo haray, iyo suurtogalnimada mid saddexaad, sidaas darteed samaynta dhererka loo baahan yahay.

Qalloocinta soo noqnoqda waxaa laga yaabaa in qaybaha isku-xidhka la isku xidho si loo sameeyo halbeeg dhererka loo baahan yahay.Haddii kale, haddii sanduuqyadu ay leeyihiin dhinacyo gacmeed oo aad haysato adalool clampbar , ka dib waxaa laga yaabaa inay dhakhso badan tahay in sanduuqyada loo sameeyo si la mid ah sida saxarada gacmeedka .(Fiiri qaybta xigta: TRAYS)

Dibnaha leh sanduuqyada

Sanduuqyada dibinta waxaa lagu samayn karaa iyadoo la adeegsanayo habka caadiga ah ee xirmooyinka gaaban haddii mid ka mid ah cabbirada uu ka weyn yahay ballaca xajinta (98 mm).

11 .Adigoo isticmaalaya xajinta dhererka dhererka buuxa, samee dhererka laalaabyada xigmadda leh ee 1, 2, 3, &4 .

2018-03-21Dooro xajin gaaban (ama suurtogal ah laba ama saddex isku dheggan) oo leh dherer ugu yaraan ballac bishimo ah oo ka gaaban ballaca sanduuqa (si hadhow looga saaro) .Foom laalaabyada 5, 6, 7 & 8. Markaad samaynayso laalaabyada 6 & 7, ka taxaddar inaad hagto tabsyada geesaha gudaha ama dibadda dhinacyada sanduuqa, sida la rabo.

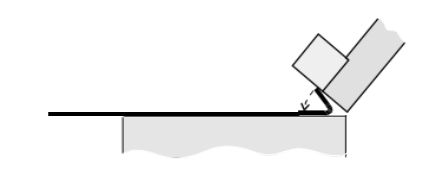

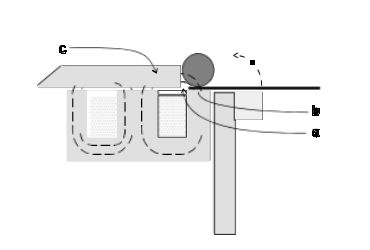

SAMEYNAYA A GOOGAYN EDGE

Cidhifyada duuban waxaa lagu sameeyaa iyadoo lagu duubo qaybta shaqada agagaarka birta wareegsan ama qayb tuubo leh oo dhumuc weyn leh.

11 .Dhig qalabka shaqada, clampbar iyo birta duubka sida muuqata.

a) Hubi in clampbar-ku aanu ku xidhmin cidhifka hore ee mishiinka"a” maxaa yeelay tani waxay u oggolaanaysaa qulqulka magnetic inuu dhaafo birta rogroga oo markaa isku-qabsigu wuxuu noqon lahaa mid daciif ah.

b) Hubi in baalku ku dul taagan yahay birta hore ee mishiinka ("b") oo aan dib ugu noqon qaybta aluminium ee dusha sare.

c) Ujeedada xajintu waa in la bixiyo dariiqa magnetic ("c") gudaha birta duubista.

2018-03-21Ku duub qalabka shaqada sida ugu fog ee suurtogalka ah ka dibna dib u dhig sida la muujiyay.

3 .Ku celi talaabada 2 sida loo baahdo.

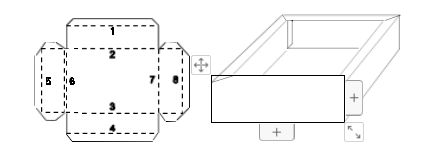

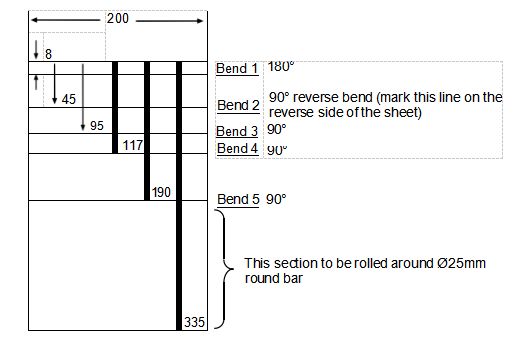

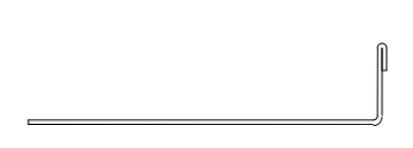

TILMAAMAHA FOR SAMEYNAYA TIJAAB QAYB

Si aad u barato mashiinkaaga iyo nooca hawlgalada

waxaa lagu samayn karaa iyada, waxaa lagu talinayaa in tijaabo -piece la sameeyo sida

hoos lagu sifeeyay:

11 .Dooro gabal bir khafiif ah ama aluminium qaro 0.8 mm ah oo goo goo

320 x 200 mm.

2018-03-21Ku calaamadee xadadka xaashida sida hoos ku cad:

3 .Is waafajiLaabi1oo ka samee dibinta cidhifka shaqada .(fiiri "FURAAN LA LABAY")

4 .U rog qaybta tijaabada oo ku sidi xajinta hoosteeda, adigoo u dhaafaya cidhifka isku laabma ee xaggaaga.Xidhiidhka hore u leexi oo safLaabi2.Ka dhig laabtan ilaa 90°.Qaybta tijaabada hadda waa inay u ekaataa sidan:

... TIJAAB QAYB

5 .Ka rog qaybta tijaabada oo sameeLaabi3, Laabi4iyoLaabi5mid kasta ilaa 90 °

6 .Si loo dhamaystiro qaabka, gabalka soo hadhay waa in lagu rogrogiyaa bir wareeg ah dhexroor 25mm ah.

• Dooro 280 mm clamp -bar oo dhig, qaybta tijaabada iyo birta wareega ee mishiinka sida ka muuqata hoos"RIDAY GELIN” horraantii buug-gacmeedkan .

• Ku qabo baarka wareega booska gacanta midig oo mari hor-u-qabsiga adigoo riixaya oo ku haya badhanka START gacanta bidix .Hadda isticmaal gacantaada midig si aad u jiido gacanta sidii adigoo samaynaya foorar caadi ah (badhanka START ayaa laga yaabaa in la sii daayo).Isku duub

workpiece sida ugu fog ee suurtogalka ah (qiyaastii 90 °).Dib u dhig qaybta shaqada (sida hoos ku cad"Samaynta Wareegga Wareegga ah”)oo haddana duub .Sii wad ilaa duubku xidhmo.

Qaabka tijaabada hadda waa dhameystiran yahay .

Waqtiga boostada: Oct-11-2022